78″ Stroke Telescopic Dump Trailer Kit | 12 Ton

*Free Shipping to a Commercial/ Business Address or Freight Terminal Near You in the Lower 48 States. Residential and Lift gate Deliveries Will Require an Additional Fee. We will find the Freight Terminal for you. Contact us for more information, Thank you.*

$2,395.00

Introducing telescopic lifts for dump trailer applications. With over 30 years of experience in the construction and application of the Power Hoists, Premium Supply has become an industry leader in the US trailer market and are excited to offer Telescoping Cylinder Dump Kits.

- Capacity and dump angle are approximate. Capacity is calculated using a evenly distributed load.

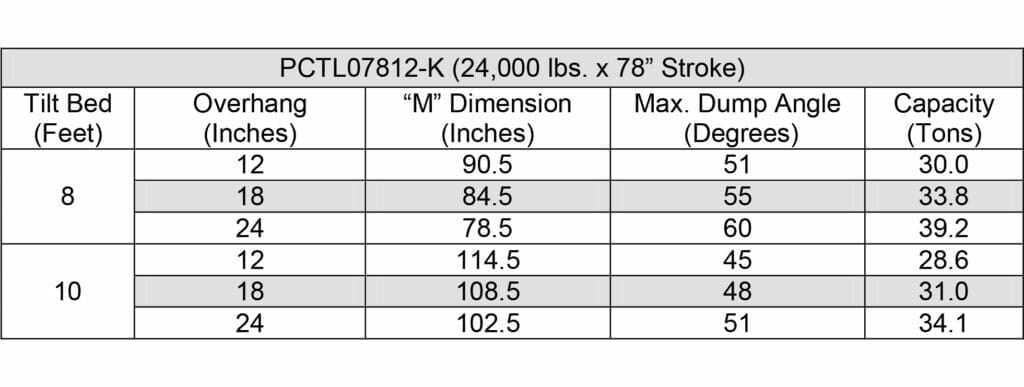

- The PCTL07812-K Telescopic Cylinder is Capable of 24,000 lbs of Push.

- Perfect for 8′ or 10′ Dump Beds.

78″ Stroke Telescopic Dump Trailer Kit | 12 Ton Includes:

- 78″ Stroke Telescoping Cylinder

- 24,000 lbs. of Push

- Hydraulic Power Unit (HPU)

- H-Frame

- Hydraulic Hose Assembly

- Hydraulic Fittings

- Bridon Load Control

- Safety Arm and Safety Arm Cup

- Safety Arm Storage Arm Bracket

- Hinge, Battery Cables, and Rubber Strap

- Installation Manual

See Chart Below for Lifting Capacities Based Off of Dump Bed Lengths, Overhangs and Dump Angles.

78″ Stroke Telescopic Dump Trailer Kit | 12 Ton

Telescopic Cylinder Bleed Procedure:

1. The highest point of the hydraulic circuit is the telescopic cylinder bleed screw. Remove the bleed screw and sealing washer.

2. Gradually fill the cylinder by pressing the “UP” button on the remote control station. This should be done in an intermittent manner with a rag over the bleed screw hole. Fluid will come out of the bleed screw hole at high velocity if the cylinder is filled too quickly. Keep fluid in the reservoir to prevent air from entering system.

3. Once a steady stream of fluid comes out the bleed screw hole, stop filling and install and tighten bleed screw.

4. Press and hold the “UP” button and keep the oil reservoir filled just enough to keep air out of system. Fully extend the cylinder.

5. Press and hold the “DOWN” button until cylinder is fully retracted. Watch oil reservoir level in case of overflow.

6. To remove any remaining air in the system, fully retract the cylinder and remove bleed screw. Repeatedly tap “UP” button until only fluid is coming out of bleed screw hole. Replace bleed screw.

7. Wipe cylinder clean and replace any lost oil.

8. Fully extend the cylinder. The cylinder should extend smoothly without any jerky motion. Watch oil level in reservoir. If cylinder has a jerky (stop and go) motion, retract the cylinder and repeat steps 6 thru 8 until cylinder operated smoothly.

9. Check oil level in reservoir. Bleed procedure is complete.