How to Measure a Trailer Axle 3

How to Measure a Trailer Axle: A Step-by-Step Guide

When replacing or upgrading a trailer axle, getting accurate measurements is crucial for ensuring compatibility and performance. This guide will walk you through the process of measuring a trailer axle correctly, helping you avoid costly mistakes and ensuring a perfect fit.

Why Proper Trailer Axle Measurement Matters

Choosing the right axle for your trailer affects its load capacity, handling, and safety. An incorrect measurement can lead to improper alignment, tire wear, and even structural damage. To get the best replacement axle, you’ll need to measure key dimensions accurately.

Tools You’ll Need

✅ Tape measure

✅ A straight edge or level

✅ Notepad or phone for recording measurements

4 Easy Steps to Accurately Measure Your Trailer Axle

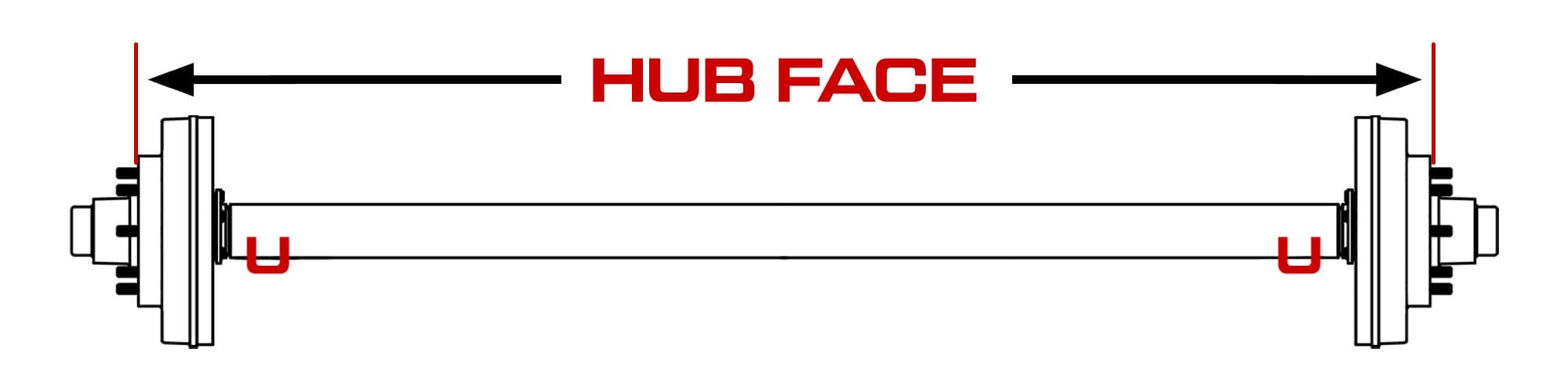

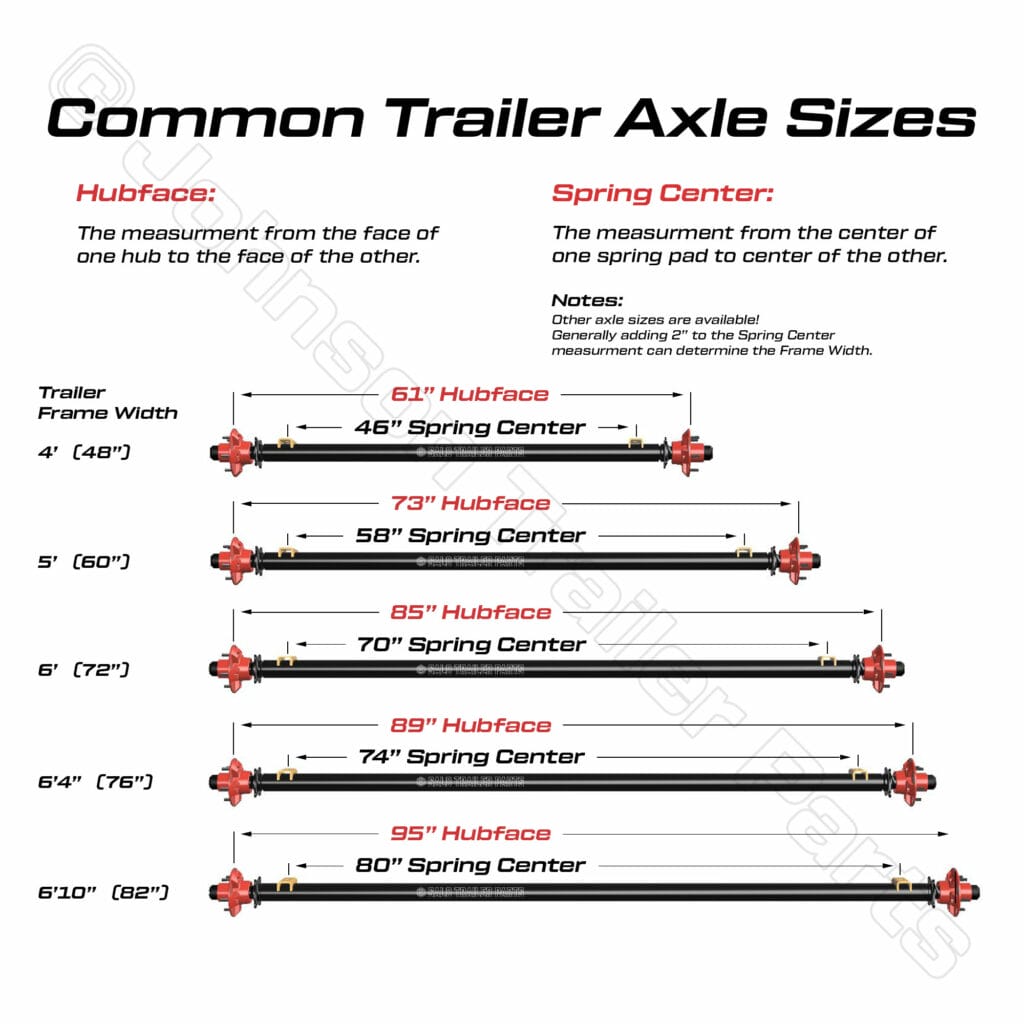

1. Measure the Hub Face

The hub face measurement is an essential factor in axle sizing. It refers to the distance between the outer faces of both hubs, specifically where the back of the wheel makes contact with the hub. This measurement determines the axle’s overall width and ensures proper wheel alignment under your trailer. Below, you’ll find an image highlighting the hub face in red on four different axle types for reference.

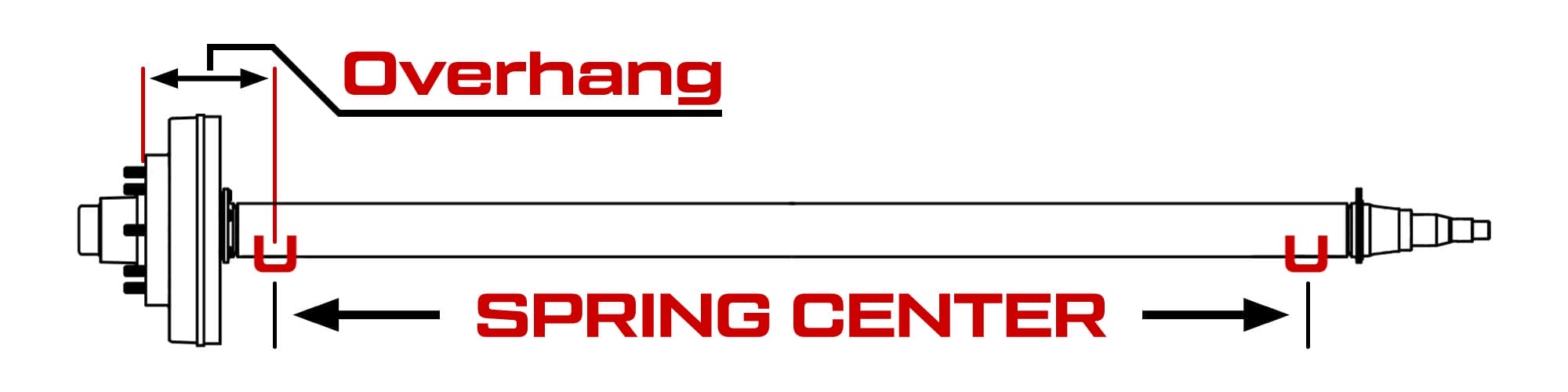

2. Measure the Spring Center Distance

The spring center measurement refers to the distance between the center points of the spring pads, where the axle attaches to the trailer’s leaf springs. Measuring this accurately ensures proper alignment with your trailer’s suspension system. In most cases, adding 2 inches to this measurement provides a good estimate of the trailer’s frame width. Refer to the spring center diagram below for visual guidance.

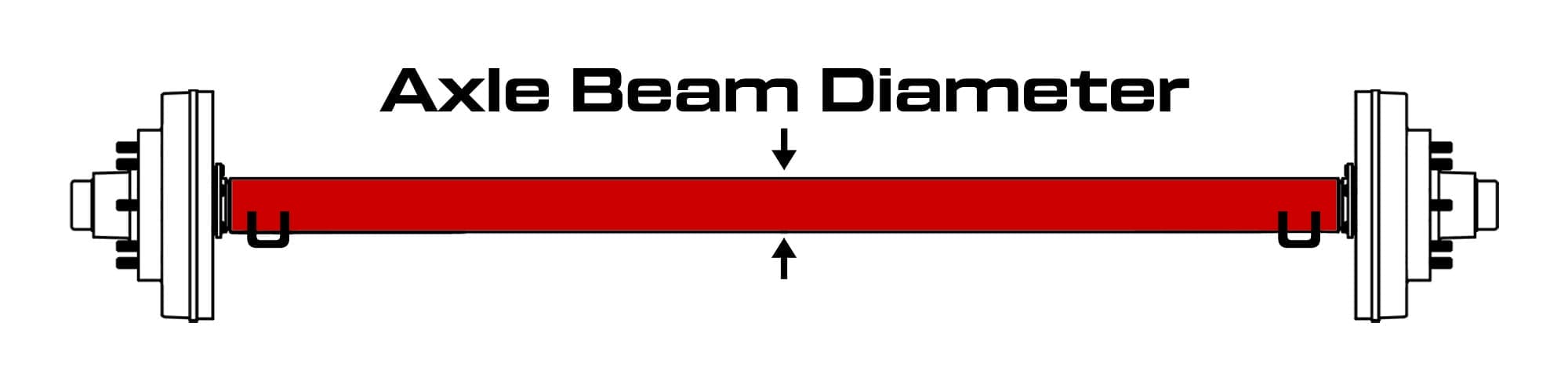

3. Identify the Axle Weight Capacity

Determining the weight capacity of your trailer axle is essential for safe towing and proper load distribution. Most axles have a weight rating label, typically located on the axle tube. If the label is missing or unreadable, you can estimate the capacity based on key measurements, such as axle beam diameter and bolt pattern.

Axle Beam Diameter

The diameter of the axle beam is a strong indicator of its weight capacity. Use a tape measure or calipers to measure from the top of the beam to the bottom for accuracy.

- 3,500 lb axles – Standard round tube diameter: 2 3/8 inches

- 5,200 lb to 7,000 lb axles – Typically 3 inches in diameter

See diagram below for reference.

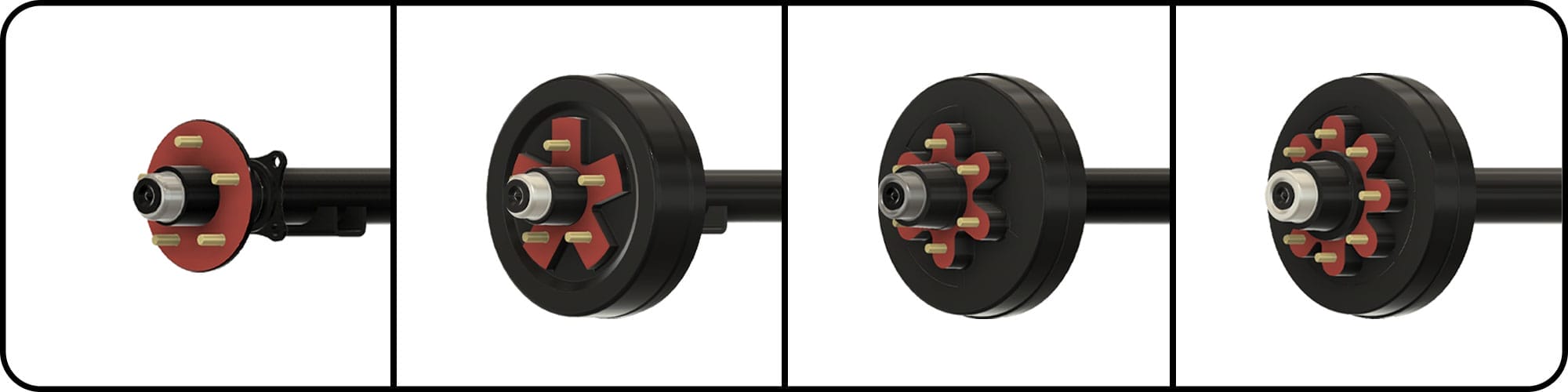

4. Bolt Pattern

Matching the correct bolt pattern ensures compatibility with your trailer wheels. Here are the common configurations based on axle weight rating:

- 3,500 lb axles – Most commonly 5 lug on a 4.5-inch pattern, though four different 5-lug patterns exist.

- 5,200 lb axles – Typically 6 lug on a 5.5-inch pattern.

- 7,000 lb axles – Usually 8 lug on a 6.5-inch pattern.

Common Trailer Axle Sizes & Weight Ratings

|

Axle Tube Diameter |

Estimated Weight Capacity |

Typical Bolt Pattern |

|---|---|---|

|

1.75” |

2,000 lbs |

4 or 5 Lug |

|

2.375” |

3,500 lbs |

5 lug on 4.5” (most common) |

|

3” |

5,200 – 7,000 lbs |

6 lug on 5.5” (5,200 lb) / 8 lug on 6.5” (7,000 lb) |

|

5” |

9,000 – 10,000 lbs |

Varies |

Understanding Bolt Patterns

Knowing how to accurately measure your bolt pattern is essential, particularly for 5 lug configurations, which have multiple variations. Misidentifying the bolt pattern can lead to compatibility issues with wheels and hubs.

Check out our blog on How to Measure a 5 Lug Trailer Axle Bolt Pattern for a step-by-step guide!

3 Additional Ways to Measure a Trailer Axle

When measuring a trailer axle, certain situations—such as missing hubs or a bent axle—can make the process more challenging. However, the following methods can help you determine the correct replacement measurements.

1. Measuring Without an Axle Hub or When the Axle Is Bent

If you’re missing an axle hub or dealing with a bent axle, you can use the Spring Center + Overhang Method to approximate the correct axle size.

Key Measurements:

- Spring Center – The distance between the centers of the two spring mounts on the axle. This measurement determines how the axle aligns with the trailer frame.

- Overhang – The distance from the spring center to the end of the axle where the hub is mounted. Measure this distance on one side and multiply by 2 to get the total overhang.

- Calculation Formula:

- Spring Center + (Overhang × 2) = Hub Face Measurement

See the diagram below for a visual reference.

2. Measuring When Both Axle Hubs Are Missing (Flange-to-Flange Method)

If both axle hubs are missing, you can determine the correct axle size by measuring the distance between the outer faces of the brake flanges at each end of the axle. Then, use the following reference values to estimate the hub face measurement:

|

Axle Rating |

Flange-to-Flange Adjustment |

|---|---|

|

2,000 lb Axles |

Add 7 inches to the flange length |

|

3,500 lb Axles |

Add 6 inches to the flange length |

|

6,000 lb Axles |

Add 9 inches to the flange length |

|

7,000 lb Axles |

Add 9 inches to the flange length |

See the diagram below for accurate measurement points.

3. Measuring Overall Length to Determine Hub Face

If your axle is missing both brake flanges and hubs, you can estimate the hub face measurement by using the overall axle length. Simply subtract the following amounts from the overall length based on your axle’s weight rating:

|

Axle Rating |

Overall Length Adjustment |

|---|---|

|

2,000 lb Axles |

Subtract 5 inches |

|

3,500 lb Axles |

Subtract 5 inches |

|

6,000 lb Axles |

Subtract 6 inches |

|

7,000 lb Axles |

Subtract 6 inches |

This method provides an alternative way to determine hub face width when other measurements are unavailable.

Refer to the diagram below for a visual guide.

Final Tips for Replacing Your Trailer Axle

✅ Double-check measurements before ordering a replacement to ensure a perfect fit.

✅ Consider upgrading if your current axle is close to its weight capacity for added durability and safety.

✅ Check brake compatibility, especially when switching between axle types, to avoid installation issues.

✅ Verify bolt patterns to ensure your existing wheels will fit properly without requiring additional modifications.

Need a New Trailer Axle? We’ve Got You Covered!

At Johnson Trailer Parts, we carry a wide range of replacement trailer axles for everything from utility trailers to heavy-duty equipment haulers.

Shop our selection now or contact us for expert advice!

Call us at: 602-292-9690

Email us at: Sales@johnsontrailerparts.com

My axel where the wheel hub goes measured, using calipers, 1.05 inches. Would this be considered a 1 inch axel?

When using calipers to measure your axle spindle, if the measurement is 1.05 inches, this generally indicates a 1-inch spindle. Spindle sizes are typically nominal (rounded) measurements, and slight variations like 1.05 inches are still considered within the tolerance for a 1-inch axle spindle.

My axle measures at 1.65″ in diameter. Having such a hard time finding this size. Is that considered 1.75 or 1.5?